ACE ResiMesh

The Smarter Base for Resin-Bound Surfacing

The Smarter Base for Resin-Bound Surfacing

Traditionally, resin-bound systems in the U.S. have required full excavation, even when the existing base (concrete, pavers, or tiles) was still structurally sound.Why? Because installing resin directly onto those surfaces can lead to reflective cracking, movement, and debonding — causing costly repairs or complete failure.

ACE ResiMesh changes that.

Originally developed for high-stress environments like highways, ACE ResiMesh is a high-performance composite made from glass fiber and polypropylene. It’s designed to bridge surface movement, reinforce joints, and create a stable, long-lasting base for resin-bound surfacing — without the need for digging out.

The result? Faster installations, lower costs, and stronger, more reliable surfaces.

FAQsHere’s why more installers and property owners are choosing ResiMesh as the smarter foundation for resin-bound surfacing:

Overlay directly onto existing bases — no demolition required

Bridges joints and absorbs movement to prevent cracking and delamination

Reinforces the surface to extend the life of the resin system

Cut installation time, ideal for busy residential or commercial sites

Helps maintain permeability in SUDS-compliant resin systems

Minimal disruption, perfect where excavation isn’t practical

ResiMesh is installed directly onto a structurally sound surface, such as concrete, block paving, or tiles, and acts as a reinforcement layer beneath the resin bound system.

The mesh spans across hairline cracks, expansion joints, and minor imperfections, preventing reflective cracking from transferring through to the resin surface.

By allowing a small amount of flex, ResiMesh accommodates minor shifts or thermal expansion in the underlying base—essential for overlays on older substrates like block paving or concrete.

ResiMesh disperses pressure more evenly across the surface, helping to reduce stress points and prolong the life of the resin finish.

Ace ResiMesh acts as a decoupling layer when laid over existing surfaces like concrete or tarmac. It helps absorb movement in the base, preventing reflective cracks from appearing in the resin bound finish. This added flexibility ensures a longer-lasting, seamless surface — ideal for overlays and refurbishments.

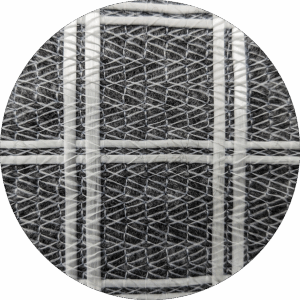

Material: Glass filament grid structure

ResiMesh is the go-to solution for installers working on resin-bound projects where the existing base is solid but flawed. It’s ideal when you want to avoid the time, mess, and cost of excavation without compromising the quality of the finished surface.

Perfect for upgrading tired block paving or concrete drives without digging them out. ResiMesh strengthens the base and prevents cracking, even under vehicle loads.

Quickly resurface cracked or uneven paths and patios to create smooth, permeable walkways without the need for disruptive groundwork.

Ideal for busy locations where minimal downtime is essential. Installers can lay resin over structurally sound bases with confidence that it will last.

Whether it’s a tight deadline or restricted site access, ResiMesh helps reduce project timelines and eliminate the need for heavy machinery or plant hire.

With ACE ResiMesh, you can install resin-bound surfacing directly onto a well-compacted granular base (Type 1 or Type 3 equivalent) without pouring concrete or asphalt.

This approach is perfect for light-use areas like paths, patios, and pool decks — cutting time, cost, and materials while still delivering a strong, stable finish.

|

Sample ID |

Description |

Flexural Strength (MPa) |

Compressive Strength (MPa) |

|

25-0699 |

Unmatted Ace Resin Bound |

4.56 |

24.68 |

|

25-0700 |

Matted Ace Resin Bound (with Ace ResiMesh) |

6.38 |

23.14 |

Ace ResiMesh increased flexural strength by ~40% (from 4.56 → 6.38 MPa), improving resistance to bending and cracking while maintaining comparable compressive strength.

Exceeds F6 Screed Class – BS EN 13813 defines F6 at 6 MPa flexural strength. Ace Resin with Ace ResiMesh delivers 6.38 MPa, surpassing this benchmark. This means Ace Resin, when applied to Ace ResiMesh is Stronger than Standard Concrete – Typical unreinforced concrete achieves only 3–5 MPa in flexure. Ace ResiMesh pushes well beyond this range. (EngineeringCivil.org)

Ace ResiMesh transforms standard resin bound surfacing into a reinforced system that performs above industry benchmarks—delivering strength, resilience, and peace of mind.

Ace ResiMesh is manufactured to the highest standards under an EN ISO 9001-certified Quality Management System, ensuring consistent performance and reliability. It contains no VOCs, making it a safer, more environmentally friendly choice.

Ace ResiMesh is designed to improve installation speed and reduce costs, providing an efficient, cost-effective solution for resin bound surfacing without compromising on durability or quality.

| Characterstic | Unit | Value |

| Roll Width | m | 1 |

| Roll Length | m | 100 |

| Product Weight per roll | kg | 40 |

| Index Strength (1) | kN/m | 100 |

| Typical strain at failure (1) | % | 3 |

| Elastic modulus of glass filments | Gpa | 80 |

| Polymer of Paving Fabric | pp |

(1) Index property based on testing the individual glass filaments in accordance with ASTM D 3822. Index properties will differ from testing results on the final product (e.g. to ISO 10319).

Not usually — unless you’re using ResiMesh. Laying resin directly onto concrete or block paving without reinforcement can lead to reflective cracking, movement, and debonding. ResiMesh bridges these weaknesses, allowing you to overlay stable existing surfaces confidently.

ResiMesh can be installed over any solid, stable base that’s in good structural condition, including:

It should not be used on unstable, crumbling, or failing bases.

If the existing surface is moving or breaking apart, it will need to be replaced before installation.

Yes — when used as part of a permeable resin-bound system, ResiMesh allows water to drain through as intended and won’t block or reduce surface permeability.

This helps your project comply with local stormwater management and drainage regulations often required by U.S. municipalities for patios, walkways, driveways, and other paved areas.

ResiMesh is installed directly onto the existing base before the resin-bound system is applied.

It’s lightweight, easy to cut, and quick to position, making it simple to handle on site.

Just roll it out over the prepared surface, cut to fit, and secure it in place before laying the resin mix on top.

If you need guidance on best practices or installation support, our U.S. team can walk you through the process.

Absolutely. ResiMesh was originally developed for high-load environments like highways, so it’s more than capable of handling commercial use.

It’s suitable for everything from residential driveways and walkways to public sidewalks, courtyards, parking areas, and commercial entrances — anywhere you need a strong, stable base without full excavation.